Different Types Of Welding: An Essential Guide

Working with metal is both exciting and empowering. As the sparks fly and the heat turns up, welders are able to transform some of the world’s strongest materials into the shapes and products they envision. This skill requires work and practice to acquire, and it’s best learned with the assistance and guidance of industry professionals.

Learning the ropes of a new trade can be time consuming. You need to become familiar with the entire working process from start to finish and master each level before moving on. This attention to detail is what makes a great welder and a more versatile potential employee. There are four major types of welding procedures that students at Lincoln Tech must learn in order to become successful welders working in the field. Lincoln students have the unique opportunity to get comprehensive hands-on training from field-experienced instructors. With guidance from some of the best in the industry, students will master the four most popular types of welding procedures.

Different Types of Welding Processes

The 4 Most Popular Types of Welding Techniques

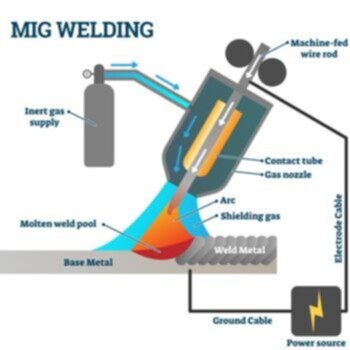

Gas Metal Arc Welding (GMAW/MIG)

This type of welding is also referred to as Metal Inert Gas (MIG Welding). It uses a shielding gas along the wire electrode, which heats up the two metals to be joined. This method requires a constant voltage and direct-current power source, and is the most common industrial welding process which includes plate and large bore pipe.

The Gas Metal Arc Welding Process

MIG welding uses four primary methods of metal transfer:

- Globular transfer produces a rougher weld bead due to metal droplet size and the propensity for spattering. This method is useful for welding thick metal plates in horizontal positions.

- Short-circuiting works as the name implies – the welding wire contacts the base metal in a quickly repeated tapping method many times per second. Because little spattering is produced in the process, this method can be used in any welding position.

- Spray Transfer transmits tiny droplets of molten metal in such a steady fashion that it maintains a steady-contact arc weld during the process. Even though this method produces little splatter, it is best to use on horizontal pieces that are thick and flat.

- Pulsed-spray is very similar to Spray Transfer, but uses a high-low current pulse to allow micro-cooling periods. Because of this type of delivery, this process can be used on a wide variety of metal plate thicknesses, and in almost all welding positions. Note that when we use the term “cooling” when describing pulsed-spray, the moments of lower voltage that provide a cooler weld are still several thousand degrees Fahrenheit. It is only considered cooler relative to the high-voltage portion of the cycle. All welding uses extreme temperatures.

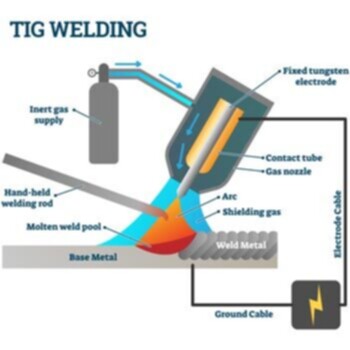

Gas Tungsten Arc Welding (GTAW/TIG)

Also known as TIG welding, the most common use for this type of welder is to join together thick sections of stainless steel or non-ferrous metals. It is an arc-weld process that uses a fixed non-consumable tungsten electrode in a gas-shielded environment to create the welding pool in which the filler material is used to create the weld. This process is much more time consuming than MIG, Stick or Flux Cored Arc Welding.

The melting point of non-ferrous metals vary considerably, so care must be taken in identifying the composition of the base metal. Stainless Steel and Steel both contain Iron, however, to be considered Stainless Steel, the metal must contain at least 11% Chromium. Carbon Steel melts in the 2,600 to 2,800-degree F range.

The presence of 11% chromium in stainless steel narrows that temperature range to the 2,750+/- degree F mark. But nothing shows a welder's skill more than the intricate ability to TIG weld aluminum. This skill takes a steady hand, trained eye, and an artistic touch to create a smooth, amazing weld. We discuss this process in greater detail in our article on the uses of gas tungsten arc welding and important safety information.

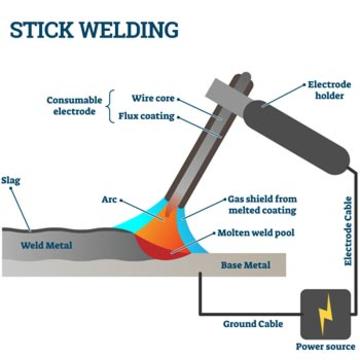

Shielded Metal Arc Welding (SMAW)

With this particular welding procedure, the welder follows a manual process of stick welding. This type of welder uses a consumable electrode stick, and electric current is used to form an arc between the stick and the metals to be joined.

Shielded metal arc welding is often used in the construction of steel structures and in industrial fabrication to weld iron, steel and using the open V-Groove when welding with mild steel pipe.

It is vital that the welder must be able to weld to a level in which their work can pass a destructive type of bend test. While shielded metal arc welding is used to join carbon steel, alloyed steels, stainless steel, cast iron, and ductile iron, it can also be used for some non-ferrous metal applications like Nickel and Copper. It is rarely used on Aluminum.

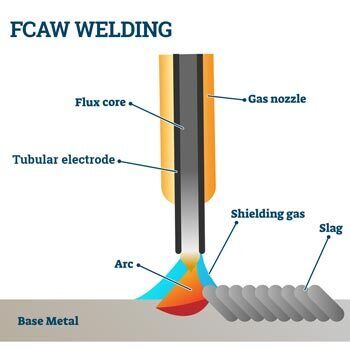

Flux Cored Arc Welding (FCAW)

This was developed as an alternative to shield welding. The semi-automatic arc weld is often used in construction projects, thanks to its high welding speed and portability. This method has many variables making it applicable in a variety of welding projects. Variables often depend on the type of welder being used, and what type of wire was chosen for the application.

The flexibility is broadened by the many operating angles, voltage levels, polarity used, as well as the speed of the wire feed. Due to the potential of faster welding speeds, the newly joined metal cools quicker. If the welder is using a flux cored wire, he or she must be on the lookout for porosity in the welded joint.

Flux Cored Arc Weld type is best used in either outdoor settings or under industrial ventilation hoods, due to the amount of smoke and fumes created during the welding process.

Different Types of Welding Processes Used in Heavy Industry and Precision Manufacturing

Once you master the four most popular types of welding taught at Lincoln Tech, you’ll want to continue developing your skills and knowledge in the field. The following types of welds are specialized procedures used in specific industries. The following procedures are not currently taught at Lincoln Tech, but you may want to familiarize yourself with these concepts in case you want to build skills in these techniques later.

Electroslag Welding Process (ESW)

This is an advanced welding process used to join thin metal plates together edge-to-edge vertically. The weld occurs between the edges of the two plates, in lieu of being applied to the outside of a joint. Instead, consumable metal guides are placed between the two plates to position them for joining. Through this guide a copper electrode is passed, and it will become the filler for the joint. The arc is created when an electrical current is applied. The welding forms at the beginning of the seam, and slowly proceeds through the target weld area. The movement is controlled by a machine, and the process is fully automated after initial set-up of the plates & guides.

Electroslag welding is used mainly to join low carbon steel plates that are very thick. It can also be used on structural steel if certain precautions are observed. ESW relies on slag conduction to carry the welding current.

Advantages of Electroslag Welding

- Produces high-quality welds.

- Can be used for welding thick sections of metals.

- Can be used for repairing castings.

- Can be used for fabricating heavy-duty structures.

Disadvantages of Electroslag Welding

- Requires special equipment.

- Requires highly skilled operators.

- Is a slow process.

- Is a costly process.

Who uses Electroslag Welding?

Electroslag welding is used by industries such as shipbuilding, power generation, and petrochemical applications. It is also used in the construction of offshore oil platforms, bridges, and pressure vessels.

Plasma Arc Welding (PAW)

Plasma arc welding, or PAW, is similar to GTAW, but it uses a smaller arc and lower voltages which increase the precision of the weld. This precision and voltage allows the use of this process to assemble delicate and heat sensitive devices, such a microchips and medical devices.

The torch can also achieve very high temperatures in small spaces. Gas is pressurized inside the wand, creating plasma. The plasma is then ionized, making it electrically conductive. This allows the arc to be created, producing incredibly high temperatures that can melt the base metals. This allows plasma arc welding to be performed with no filler metal, a similarity it shares with TIG welding.

5 Perfect Plasma Arc Welding Applications

- Steel Tubing – An indispensable application for the automotive industry, steel tubing represents a major part of an automotive exhaust system, as well as some chassis structure.

- Welding Small Metal Components – the combination of small arc, low voltage and high-precision lends itself well to assembling micro components.

- An excellent weld for accurately filling butt joints.

- Welding Thin, Electronic Chips – Heat build-up is an enemy of electronics. By lowering voltages and keeping the arc small, heat spread is reduced.

- Medical Device Manufacture – The high precision of plasma arc welding makes the process suitable for assembling critical life-saving devices.

PAW can be used in a very low current mode, making it a great choice for applications that deal with delicate computer parts. Electronic chips can be sensitive to environmental factors like excess heat, which is why low current is particularly effective in these use cases. While GTAW can sometimes be used, but for highest precision plasma arc welding is the top choice.

Laser Beam Welding (LBW)

This type of welder can be used on metals or thermoplastics. As the name implies, it involves the use of a laser as a heat source to create the welds. It can be used on carbon steels, stainless steel, high-strength low-alloy (HSLA) steels like DOCOL®, titanium, and aluminum. It is easily automated with robotics and is therefore used often in manufacturing in the following industries:

- Automotive industry

- Aerospace

- Medical Devices

- Energy Industry

- Heavy Industry

- Electronics Industry

The processes and applications of laser welding are most prominent in the automotive industry, where lasers boost productivity at a low cost when welding automotive parts – such as roof, door or filler assemblies – together.

The Skills Gap Provides Employment For Many Types of Welders

With plenty of experience in these welding techniques, graduates can see many avenues open to them when they begin to look for employment. Welders often seek jobs in manufacturing, commercial construction, mining, agriculture, wholesale trade, artistic railings, and in equipment repair & maintenance. The variety in application of this skill lends to excellent employment opportunities.

Recommended Webcasts:

- Career Training Programs Help Industry Train Essential Skilled Workers

- Why A Trade School May Be Right For You - Scott Shaw on Behind The Numbers

Article originally published on April 15, 2016, and updated on April 18, 2023 to add three additional major industrial welding techniques and their uses. Detailed photographs added to display procedures.

Take the next step

Complete this simple 3-step form to get started. Click "Next" to go to Step 2.